Blow-up ratio is defined as the relation of maximum part diameter to the diameter of the extruded parison.

A maximum ratio of 5:1 should be adhered to, and if possible all work should be within a ratio of 3:1. One of the first rules to accept in part design is the use of minimum blow-up ratio to minimize nonuniform walls. Uniform wall thickness in blow molding is an extremely difficult goal to accomplish. The injection process, by necessity, uses thermoplastic materials of lower molecular weight and consequently reduced toughness and stress-crack resistance. This is not always true in plastic process equipment that relies 011 the injection of a molten material into a closed mold. The selection of raw materials offers many advantages in properties and design, since the extrusion process is capable of handling high molecular weight polymers. The unique features of the blow-molding processeliminate the need of costly assembly of parts such as found in injection molding, but special care must be exercised in part design. Numerous standard rules apply to the design of blow molded parts and are valuable in preventing serious problems and complaints in the manufacture or use of the item.

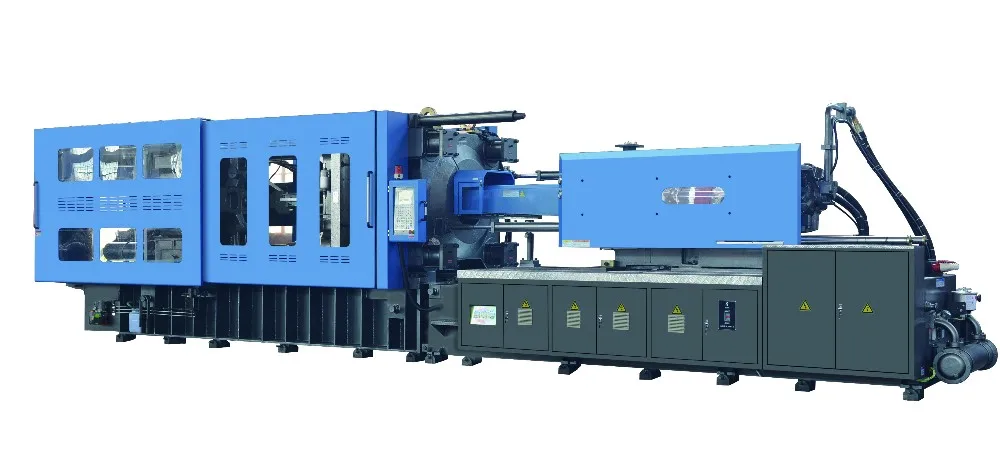

Increase the material’s tensile strength, barrier properties, clarity.low blow mold and die cost for Blow Molded products manufacturer as to injection molding.Blow molding is widely used in the industry of toy, household commodity, chemical, cosmetics, food and etc.

0 kommentar(er)

0 kommentar(er)